What Design-Build Means for Municipal Clients

Design-build skatepark delivery brings design and construction under a single, accountable team. For municipalities, this approach simplifies project management, reduces risk, and ensures that design decisions are informed by real-world constructability, cost awareness, and long-term performance.

Rather than requiring District staff to coordinate between separate designers, contractors, and consultants, Transition Construction assumes full responsibility for design coordination, budgeting, construction execution, and issue resolution. This single-point responsibility creates clarity, shortens timelines, and significantly reduces administrative burden on municipal teams.

Because builders are involved from the earliest stages of design, potential challenges related to site conditions, drainage, concrete geometry, and sequencing are identified early—when they can be addressed efficiently and collaboratively. This reduces the likelihood of late-stage redesigns, budget overruns, or compromises to skatepark performance.

Design-build also allows for continuous cost validation throughout the project lifecycle. Instead of pricing the project only after design completion, scope and budget alignment are reviewed as concepts are developed and refined. This provides municipalities with confidence that the project remains on budget and aligned with expectations from start to finish.

The result is a smoother delivery process, clearer communication, fewer surprises, and a finished skatepark that performs as intended for both users and the community.

Why Municipalities Choose Design-Build

• Single point of accountability

• Reduced coordination and administrative workload

• Early cost certainty and budget control

• Fewer change orders and redesigns

• Better constructability and long-term performance

Design Philosophy

Transition Construction’s design philosophy is grounded in the belief that successful skateparks are shaped by the people who use them, and that meaningful engagement must occur early, on site, and with intention.

Each skatepark project begins with a structured, on-site engagement session involving the local user group. Holding this engagement directly on site allows participants to respond to the space itself—its constraints, opportunities, and surrounding context—rather than reacting to abstract plans. Feedback is gathered through facilitated discussion, written input, and sketches to ensure a broad range of voices and perspectives are captured.

To support inclusivity, Transition may also provide an online feedback mechanism, allowing users who are unable to attend in person to contribute input. This ensures that the engagement process remains accessible while maintaining a clear and organized structure.

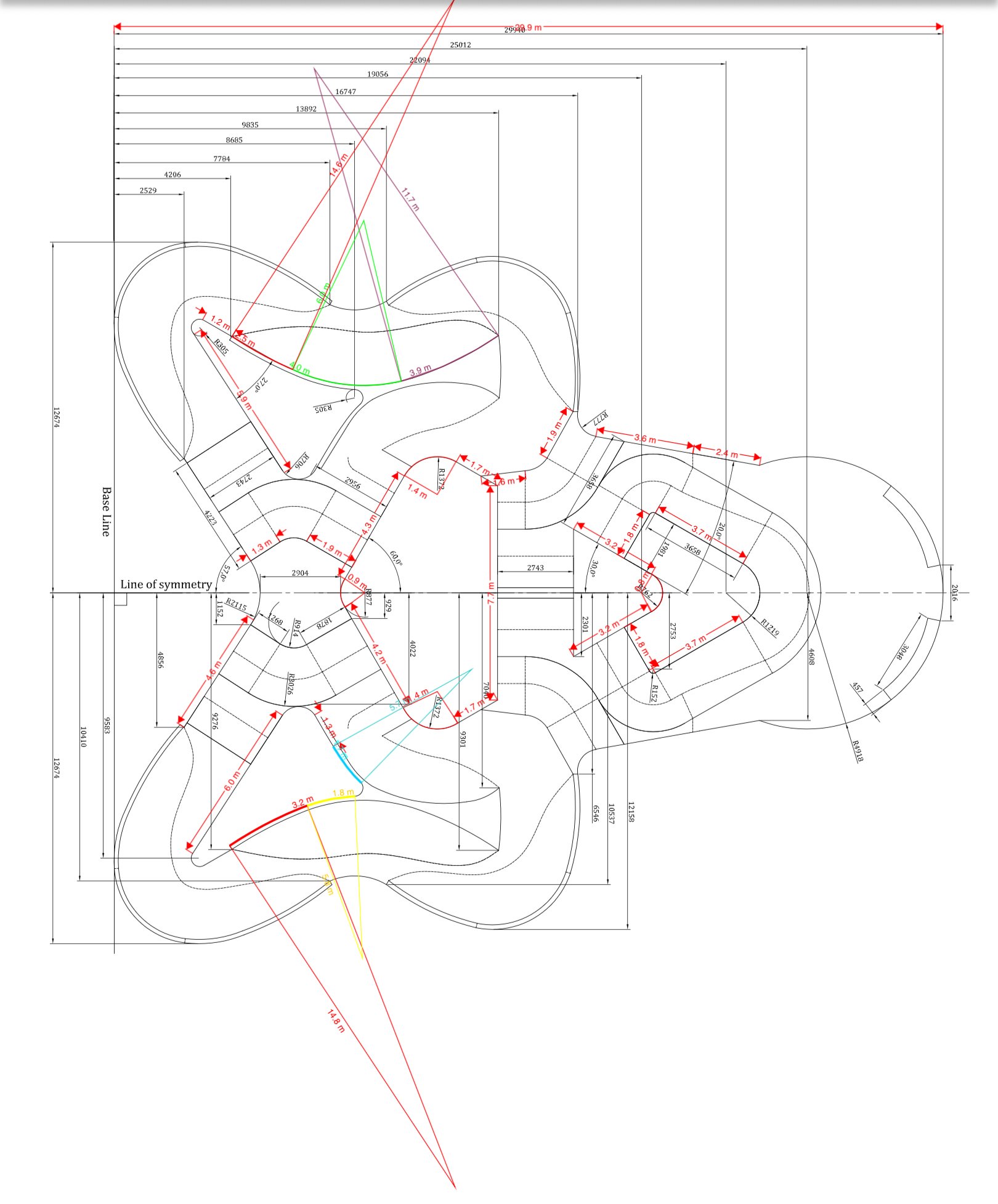

Following initial engagement, Transition develops multiple design concepts that reflect common themes, priorities, and site conditions identified through user input and technical evaluation. These concepts are presented during a second engagement session, where focused discussion helps refine the design based on what works, what does not, and how performance can be improved.

Internally, each design is reviewed by a team with diverse skateboarding backgrounds and styles, including experience in transition skating, technical street skating, flat-ground use, and barrier or curb skating. This multi-perspective review allows designs to be evaluated for flow, progression, feature balance, and long-term usability before construction begins.

Transition deliberately prioritizes quality and usability over square footage. Rather than maximizing area at the expense of performance, designs focus on properly proportioned features, meaningful transitions, and long-term engagement. Each project is treated as a unique opportunity to respond to its site and community, avoiding standardized or recycled designs in favor of original, site-specific skateparks that remain relevant over time.

Builder-Led Design Advantage

Transition Construction’s builder-led design approach integrates construction expertise directly into the design process. By involving the same team responsible for building the skatepark from the earliest stages, key considerations such as constructability, drainage, concrete geometry, joint detailing, and sequencing are addressed before construction begins.

This approach reduces risk, improves efficiency, and ensures that design intent is maintained through completion. Design decisions are informed by real-world construction experience and skatepark-specific performance requirements, resulting in facilities that function as intended, remain durable over time, and meet the expectations of both users and municipal stakeholder.

Our Design-Build Skatepark Process

Transition Construction’s design-build process is structured to provide clarity, accountability, and consistency from initial engagement through construction completion. By maintaining single-point responsibility for both design and construction, the process reduces complexity for municipal staff while ensuring that technical decisions are informed by constructability, cost awareness, and long-term performance.

Cost Control & Risk Management

Skatepark projects are highly visible public investments, and effective cost control and risk management are essential to their success. Transition Construction’s design-build delivery model is structured to manage budget, schedule, and construction risk proactively rather than reactively.

By maintaining single-point accountability for design and construction, Transition ensures that cost, schedule, and scope decisions are evaluated together. This integrated approach reduces coordination risk and prevents issues from being deferred until construction, when changes are more costly and disruptive.

A key component of Transition’s approach is continuous cost validation. Rather than pricing the project only after design completion, budget alignment is reviewed at each stage of design development. As concepts evolve, scope and costs are evaluated concurrently, allowing potential budget pressures to be identified early—when adjustments can be made efficiently and collaboratively without compromising overall performance.

Schedule risk is addressed through builder-led planning and realistic sequencing. Because construction expertise informs design decisions from the outset, construction timelines are developed based on achievable methods and seasonal realities rather than theoretical assumptions. This reduces delays and improves predictability during delivery.

When changes are required, they are managed through a transparent and structured process. Impacts to cost, schedule, and scope are clearly identified and discussed before decisions are made, allowing municipalities to remain informed without being drawn into day-to-day problem solving.

Beyond formal systems, Transition emphasizes personal accountability as a critical element of risk management. Many members of Transition’s construction team actively skate the facilities they build and are part of the Canadian skateboarding community. As a result, the performance and quality of each skatepark is not abstract—it is personal. This connection reinforces a strong internal standard of workmanship and long-term responsibility for the finished product.

The result is a delivery process that minimizes surprises, protects municipal interests, and produces skateparks that perform reliably over time.

Construction Methodology & Quality Control

Skatepark construction demands a level of precision, coordination, and craftsmanship that differs significantly from conventional concrete work. Tight tolerances, complex geometry, smooth transitions, and continuous flow require specialized techniques and experienced crews to execute correctly.

Transition Construction approaches skatepark construction with a focus on precision, consistency, and long-term performance. All work is delivered by a career, skatepark-specific construction crew with extensive experience in complex concrete geometry. Senior crew members remain actively involved throughout construction, providing continuous field-level quality control and immediate issue resolution to maintain design intent.

Construction sequencing is carefully planned to minimize seams, protect finished work, and ensure clean integration between new and existing concrete. Custom formwork, reinforcing placement, and concrete finishing are executed by crews experienced specifically in skatepark construction rather than general civil or flatwork applications.

Transition employs ACI-certified nozzlemen and trained concrete pump operators with direct experience in skatepark shotcrete placement. Shotcrete in skateparks requires a high degree of skill to achieve consistent density, accurate geometry, and smooth transitions without rebound, shadowing, or voids. Maintaining qualified personnel in these roles ensures concrete is placed efficiently, safely, and to a consistently high standard.

Joint placement, expansion, and concrete movement are managed deliberately and strategically. Skatepark performance depends on uninterrupted flow and clean transitions, which can be compromised by poorly located joints or improper detailing. Transition evaluates where construction joints, smooth dowels, and expansion joints are required—and where they must be avoided—to preserve skateability while supporting long-term structural performance.

Concrete mix design is also treated as a critical component of quality control. Unlike typical shotcrete applications that prioritize placement efficiency, skateparks require mixes that support hand shaping, tight radii, and high-quality finishes. Transition works closely with local suppliers to develop skatepark-specific mix designs tailored to site conditions, environmental exposure, and finish requirements.

Because skateparks are predominantly hand-shaped, the final performance of the facility is determined by the skill and experience of the crew executing the work. Transition’s long-term crew continuity ensures that shaping, finishing, and detailing are executed with intent and consistency rather than approximation.

Throughout construction, Transition applies a skatepark-specific safety and environmental management program addressing public interface risks, traffic control, erosion protection, concrete washout, and site housekeeping. These controls are integrated into daily operations to maintain safe, organized, and professional job sites in active public environments.

The result is a skatepark delivered with exceptional craftsmanship, consistent quality, and long-term durability—built to perform as intended from day one and for decades to come.

Safety, Environmental & Public Interface Management

Transition Construction applies a skatepark-specific safety and environmental management program tailored to public-facing construction environments. Safety planning includes early evaluation of site access, traffic management, and public interface risks, with appropriate controls implemented prior to construction and adjusted as conditions evolve.

Senior staff remain actively involved in daily site operations to ensure consistent application of safety procedures and prompt response to changing site conditions. Environmental controls—including erosion protection, concrete washout management, dust control, and site housekeeping—are integrated into daily activities in accordance with municipal requirements.

This structured approach allows projects to proceed efficiently while minimizing disruption to the public and reducing administrative burden on municipal staff.

Planning a Skatepark Project?

The most successful design-build skateparks begin before the RFP is issued.

Early collaboration helps validate budgets, reduce risk, and improve outcomes.